Air sample research

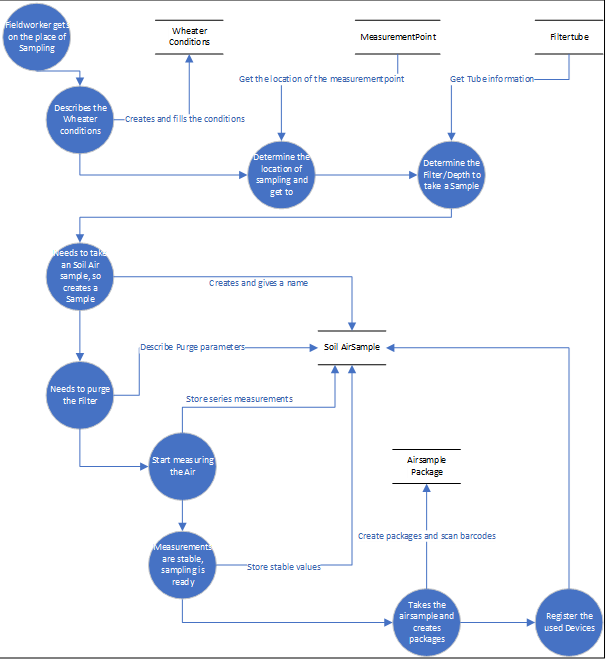

Airsamples fieldworkers process

Date: 07-01-2021

Writer: TerraIndex / Robin Huisman

This memo is about the workprocess of fieldworkers that take Air sampling in the field and register their data into TerraIndex.

Inhoud

1.1 Ambient Air sampling process. 2

1.2.1 Placing the Air sample filtertube. 3

1.2.2 Pre-Pumping and Pre-sampling operations (for Piez’Air) 5

1.2.3 Sampling the Air Sample filtertube. 6

- Main process flow

Air sampling contains 2 main flows, for each there are slightly different things to describe, but the sampling methods are similar.

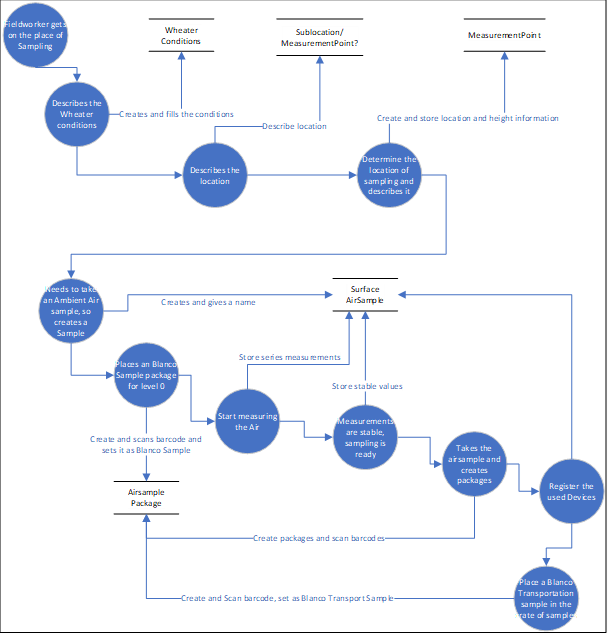

- Ambient Air sampling process

Sampling the Ambient Air, with the moment to describe and save data.

Remark on Blanco samples

In order to assess possible interference during sampling or transport, samples, called site blank and transport blank, must be taken for air measurements (soil gas and ambient air). The blanks are to be analysed according to the same measurements as the exposed media.

It should be checked that the blank value is strictly less than 10% of the sample values. If this is not the case, the measurement results should be considered with caution.

The analytical results associated with the blanks should be included in the reports of the sampling campaign and will form part of the data validation process.

According to Serpol, the field and transport blanks are realised only by ambient air sampling.

According the Franch “Practical guide for the characterization of soil and indoor air gases related to soil and/or groundwater pollution”, the field and transport blanks shall be done also for during the soil gaz sampling.

Protocol for the production of field blanks :

- Open the field blank tubes when the first sampling tubes are opened,

- Close them during the pumping phase,

- Reopen them when uninstalling the sample tubes,

- No pumping will be carried out on these field blanks.

It is essential that the blanks are conditioned under the same conditions as the supports used for the measurement in order to be able to conclude on a possible interference of the ground conditions on the supports.

A minimum of one field blank must be taken for each type of substrate used and per sampling day.

Protocol for producing transport blanks :

- Open the tubes when packaging the samples, then close them with the caps and place them in the cooler.

- No pumping will be carried out on these transport blanks.

It is therefore essential that the blanks are packaged under the same conditions as the supports used in the field to be able to conclude on a possible interference of the container on the supports (therefore the tube of the transport blank must be plugged at each end.

At least one transport blank must be produced for each type of support.

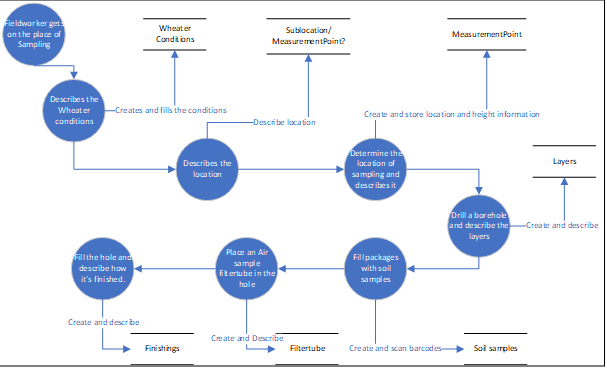

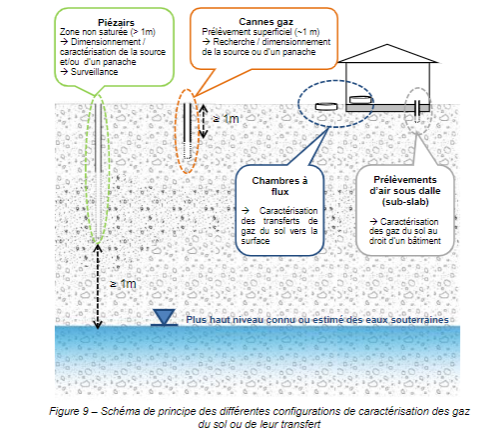

- Soil Air sampling

Consists of two flows, one is placing an Air filtertube and the second is sampling this Air filtertube.

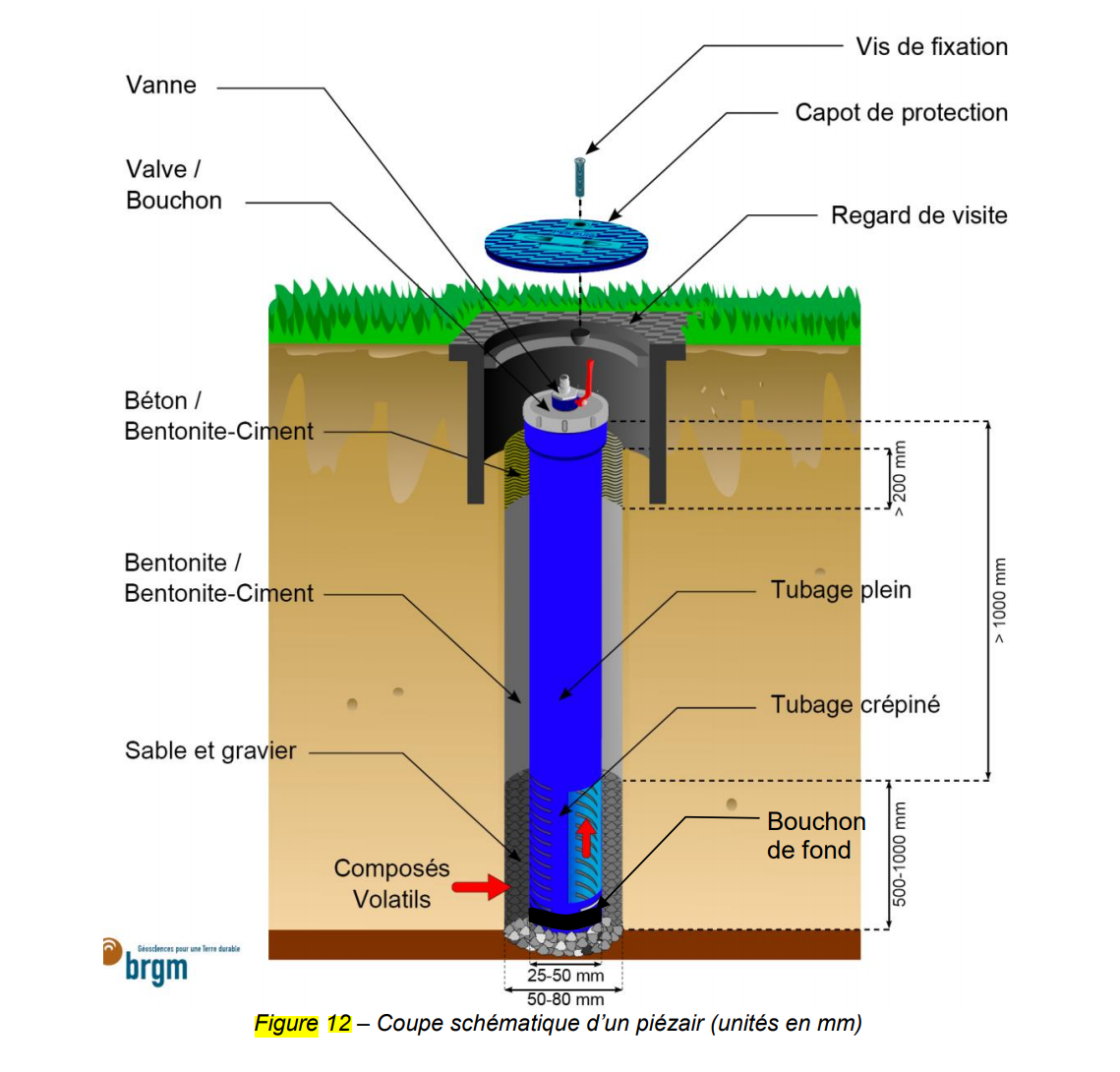

Consists of 3 flows:

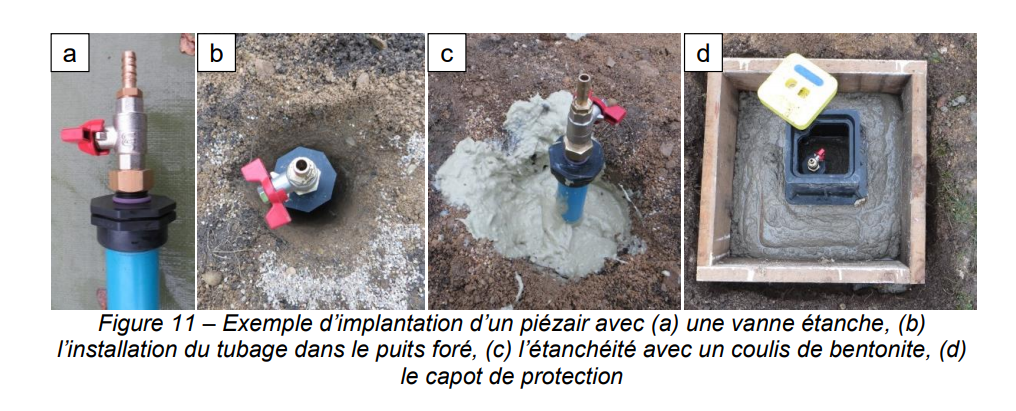

- Placing the Piez’Air (gauging tube, filter tube and finishing elements - same terminology als water gauging tubes; in the finishing “valve” should be added)[BA1] [DM2] [BA3]

- Pre-pumping & pre-sampling operations

- Gaz sampling[BA4] [DM5]

- Placing the Air sample filtertube

Process of placing the tube.

Question:

After the filtertube is placed, when will there be sampled?Directly after placement, same day, next day, next week?

Answer:

Minimum waiting period of 24 hours respected for structures that have been created by drilling (piez'air); no minimum waiting period for the other sampling methods (canne à gaz; flow chamber, air under slab)[BA6] [BA7] [DM8] [BA9] [DM10]

- Pre-Pumping and Pre-sampling operations (for Piez’Air)

Pre-pumping and Pre-sampling operations will be performed on the day of sampling, and are needed to get correct air samples. These are the actions:

- Check that there is no water

- Describe environmental conditions

- type of soil covering,

- ground conditions (wet, waterlogged, dry with vegetation, cracks in the ground)

- ventilation conditions/wind exposure

- environmental conditions (urban, rural, ..)

- groundwater level

- measurement of meteorological conditions (temperature, barometric pressure, humidity, wind speed and direction)

- control of the air-tightness of the structure

- Pre-Pumping (5 times the volume of the structure - this volume is calculated according to the internal diameter and depth of the wall- or stabilization of the parameters) at a flow rate similar to that of the sampling.

- Pre-pumping flow rate (at the beginning of and at the end of the pre-pumping)

- Semi-quantitative measures (at the beginning of and at the end of the pre-pumping)

- O2

- CO2

- PID

- Dräger

- Odour

- Soil gaz temperature

- Soil gaz humidity

- Atmospheric pressure (in the Piez’air)

- Sampling the Air Sample filtertube

After the pre-pumping and pre-sampling is done, what means enough volume of air is pumped, they start sampling the tube.

Process of the day when sampling is done:

Setting up and describing the sampling line

This is how the sampling line looks like:

These are the information that need to be described:[BA12] [DM13]

- Flowmeter

- Pump

- Moisture filter (yes or no)

- Dust filter (yes or no)

- Use of a duplicate (yes or no – if yes it is necessary to indicate the duration of the sampling for the duplicate)

- Control and adjustment of flow rates (at the beginning and end of sampling)

- Sampling supports used (number and type)

- Sampling method (active or passive)[RH14]

Taking samples

These are the information that needs to be described:

- Start time of the sampling

- End time of the sampling

- Flow rate after sampling

- Average flow rate

- Duration of the sampling

- Depth suction point

- measurement of meteorological conditions during and after sampling (total 3 times before, during and after)

- Semi-quantitative measures at the end of the sampling

- Volume of air pumped

Identification, packaging and transport of samples

These are the information that needs to be described:

- Barcode

- Blanco sample (only requested with Ambient Air)

- Transport sample (only requested with Ambient Air)

- Duplicate sample

- Conditioning

- Packaging